About

History

Willis Engineering was founded in 1976 by Ian Willis, originally repairing and manufacturing horse-floats & cattle yards from a home-based workshop in Haig Rd Attadale in suburban Perth. As work increased, the business moved to a farm shed in Hardy Rd Forrestfield. A diverse range of work ensued beyond general engineering to include industrial dissmantaling such as the Collie Power Station, East Perth Gas-works Storage Tanks and the Emu Brewery in West Perth. This led to a period of involvement in specialized Metal Recycling using engineering approaches as well as furnaces to recover a variety of recyclable and re-useable materials. During this period, the buisness continued to provide general engineering services in addition to persuing a personal interest in developing a range of miniature steam locomotives and other specialty products from a modest facility in Goodwood Parade Rivervale. Ian insisted on strong, well designed and well finished products and established a standard we follow to this day. The business relocated to the well known Riversdale rd site (pictured right) in 1985. At this location many interesting projects took place. The train for the Perth Zoo was built, the 135tonne V1213 steam locomotive was refurbished, numerous miniature locomotives where manufactured and exported, the heavy mining wheel manufacturing division commenced, The Flying Scotsman’s visit to Western Australia was conceived and managed, and the fleet of trams for the Pemberton Tramway co. was built. By January 2008 Willis Engineering had well and truly outgrown the Riversdale workshop and relocated to its current facility in Felspar rd. Welshpool.

Our Capabilities

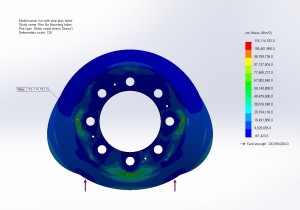

We specialise in design, fabrication, machining, fitting, submerged arc welding, vertical boring, magnetic particle inspection, production of mining wheels & rims, specialised airport related products, railway & antique machinery components, and all manner of unique pieces of equipment. To the right is an example of stress modelling for a particular application on an off road wheel rim.

We specialise in design, fabrication, machining, fitting, submerged arc welding, vertical boring, magnetic particle inspection, production of mining wheels & rims, specialised airport related products, railway & antique machinery components, and all manner of unique pieces of equipment. To the right is an example of stress modelling for a particular application on an off road wheel rim.

Our Employees

Our dedicated team has extensive industry experience, more than half have been with us for over 20 years. Our employees enjoy a great degree of flexibility and control within the workplace. Ian Willis (ian.willis@williseng.com.au) maintains overall management control of the business, primarily at a corporate level although still assists in many day-to-day aspects, problematic jobs plus design & development work. Our Works & Heavy Rim Division Manager John Binns (john.binns@williseng.com.au), who commenced with us in 1990, has extensive knowledge of the industry and developing processes that have now become the standard. Steven Shepherd (steven.shepherd@williseng.com.au), Is a NATA endorsed magnetic particle inspector and has been with us since 1987. Adam Summersett (adam.summersett@williseng.com.au) is our in house draftsman, and special projects manager with an outstanding ability to turn his hand and mind to anything. Our key workshop team, Jason, Jack, Keong, Joe, Phil & Pete, have all been with us between 8 and 28 years, as at 2016. All have become specialists in their fields and trades as well as in the types of work regularly undertaken by WLE.

Our Customers

We have a very loyal customer base, including the likes of Rio Tinto, Qantas, Westate Mining, Georgio Group, Crown & the Burswood Entertainment Complex, the Western Australian Turf Club (Perth Racing) and most Heavy (OTR) Rim Suppliers. Also, we are proud to have a long association with many of Australia’s historical machinery societies, providing specialised skills to the Hotham Valley Railway, the Perth Electric Tramway and many other machinery restorers throughout the country.

Our Suppliers

Suppliers we know and trust are an essential part of our business model. We work with our suppliers to ensure we get the quality and pricing we need, while ensuring their business remains viable. We have long & strong relationships with all suppliers that have responded to this, many have grown along with us to become specialists in some of the componentry we routinely use.

Our Products

At Willis Engineering, we manufacture long-lasting products that, where possible, use off-the-shelf components for ease of service. We also manufacture to a standard that we believe is appropriate for the conditions your product is likely to encounter in the real world. By neither under nor over engineering an item, costs are always kept as low as practicable in context with the product being fit for its intended purpose and environment. We also apply ‘safety in design’ principles by considering how items will be interacted with by people, the environment the item is likely to or will be used in as well as how it will be safely used and maintained during its service life.

We maintain a high level of trace-ability over our products and repairs etc through a robust Job Number system. Referencing the Job # recorded on an item that has been through, repaired or manufactured at our works enables access to all aspects of drawings, inspections, work done and other known history in relation to the item.

The nature of work we perform falls into 2 basic categories. 1- Repair & Manufacture of earth-moving wheels and associated equipment. 2- General Engineering.

Willis Engineering has been manufacturing all manner of items and providing practical engineering solutions to a wide and diverse range of customers since its humble beginnings in 1976.

We have had a long association with many of Australia’s historical machinery societies, and continue to provide specialised skills to the Hotham Valley Railway, Perth Electric Tramway and many other machinery restorers.

We provide a wide range of services to Western Australia’s mining industry, most particularly the manufacture and repair of heavy earth-moving wheel rims along with many specialised wheel maintenance & workshop aids.

Heavy (OTR) Wheel Manufacture and Repair

In the mid 1980’s Willis Engineering was encouraged into the wheel & Rim industry by Astra Wheels of Sydney, NSW. At the time there were few entities undertaking quality repair or manufacture of industrial wheels & rims in WA. Through dedication to technical aspects and quality work, along with prompt delivery, Willis Engineering quickly became a leading manufacturer & repairer of OTR wheels, undertaking work for both suppliers and end-users Australia wide. By the mid 1990’s, Willis Engineering had become a highly experienced local manufacturer and repairer of heavy earth-moving wheel rims, having manufactured or repaired more than 10,000 units by 2005.

In the mid 1980’s Willis Engineering was encouraged into the wheel & Rim industry by Astra Wheels of Sydney, NSW. At the time there were few entities undertaking quality repair or manufacture of industrial wheels & rims in WA. Through dedication to technical aspects and quality work, along with prompt delivery, Willis Engineering quickly became a leading manufacturer & repairer of OTR wheels, undertaking work for both suppliers and end-users Australia wide. By the mid 1990’s, Willis Engineering had become a highly experienced local manufacturer and repairer of heavy earth-moving wheel rims, having manufactured or repaired more than 10,000 units by 2005.

Pictured to the right the semi automatic arc air gouging for the preparation of the external weld on a 57″ heavy rim.

Antique Machinery

Willis Engineering has considerable experience in the repair and refurbishment of old and antique machinery. We have been involved in the restoration of a wide variety of equipment. Below is the V1213 Locomotive, refurbished at the Burswood site, and the 2 field guns in Stirling Square Guildford, restored at the new Welshpool facility

Visit our Project gallery if you have time.